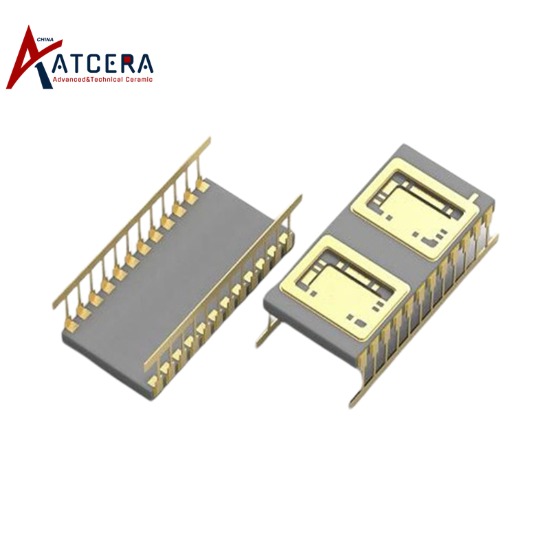

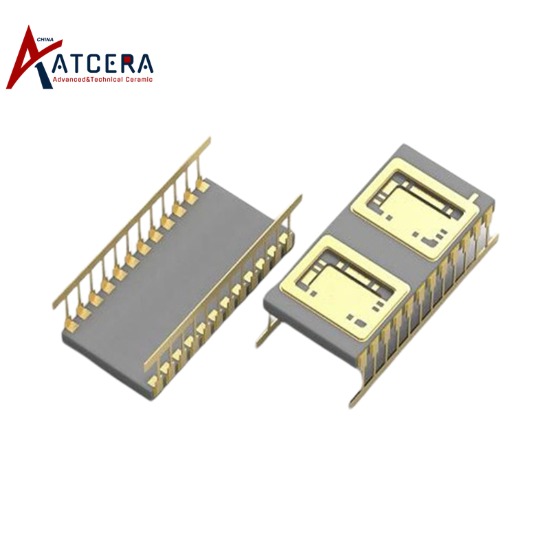

Met de snelle ontwikkeling van de micro-elektronicatechnologie worden de eisen voor elektronische verpakkingsmaterialen steeds strenger. Aluminiumnitride-keramiek, met zijn uitstekende thermische geleidbaarheid, uitstekende mechanische eigenschappen, corrosieweerstand en uitstekende elektrische eigenschappen, wordt de leider op het gebied van grootschalige koelsubstraten en verpakkingsmaterialen voor geïntegreerde schakelingen. De hoge hardheid, hoge brosheid en lage breuktaaiheid van aluminiumnitride-keramiek vormen echter een onoverkomelijke kloof, die de toepassing ervan op het gebied van ultraprecieze bewerking enorm uitdaagt. Vooral bij het nastreven van een ultraglad oppervlak met oppervlakteruwheid Ra ≤ 8 nm of zelfs RMS < 2 nm, is het effectief verminderen van oppervlaktedefecten en beschadigingen onder het oppervlak tijdens de bewerking een belangrijk probleem geworden dat de brede toepassing van aluminiumnitride-keramiek beperkt. In deze context biedt het ELID-slijpproces (Electrolytic in-process Dressing) innovatieve oplossingen voor de verwerkingsuitdagingen van AlN-substraten met zijn unieke voordelen.

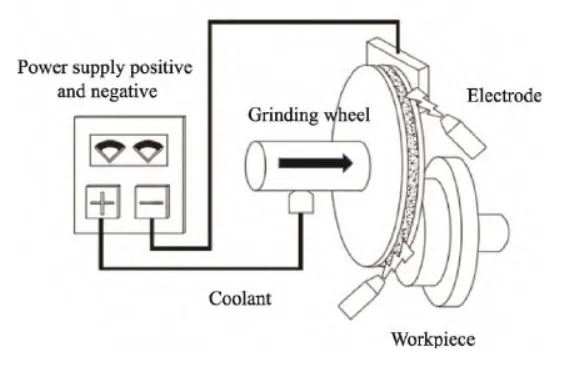

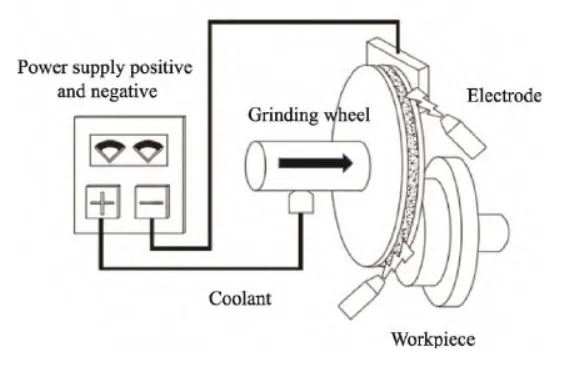

ELID-slijptechnologie is een composietspiegelverwerkingstechnologie die traditioneel slijpen, slijpen en polijsten integreert. De kern van de ELID-slijptechnologie is het realiseren van dynamisch zelfslijpen tijdens het slijpen door middel van elektrolytische insitu-dressing van slijpstenen, waardoor de slijpefficiëntie en verwerkingskwaliteit aanzienlijk worden verbeterd. De ELID-slijptechnologie is uitzonderlijk toepasbaar op brosse materialen met een hoge hardheid, zoals keramiek op basis van aluminiumnitride.

Ten eerste gebruikt ELID-slijpen een zwakke elektrolytoplossing als slijpvloeistof, die niet alleen de potentiële corrosie van de traditionele slijpvloeistof op de werktuigmachine en het werkstuk vermijdt, maar ook de verwerkingsomgeving vereenvoudigt en de productiekosten verlaagt. Belangrijker nog is dat deze technologie de temperatuur tijdens het slijpen effectief kan controleren, waardoor brandwonden aan het werkstuk, restspanningen en scheuren veroorzaakt door hoge temperaturen worden verminderd, wat essentieel is om de microstructuur en eigenschappen van aluminiumnitride-keramiek te beschermen.

Ten tweede vormt ELID-slijpen door middel van elektrolyse een uniforme en dichte oxidefilm op het oppervlak van de slijpschijf, wat niet alleen het snijvermogen van de slijpschijf verbetert, maar ook de slijtvastheid van de slijpschijf verbetert, waardoor de stabiliteit en continuïteit van de slijpschijf wordt gewaarborgd. het maalproces. Tegelijkertijd kan door de correctiestroom nauwkeurig te regelen de fijne aanpassing van de dikte van de oxidelaag worden bereikt, en vervolgens kan het slijpeffect worden geoptimaliseerd, kunnen de oppervlakteruwheid en ondergrondse schade worden verminderd, en kunnen de zware eisen van Er kan worden voldaan aan aluminiumnitride-keramiek voor ultragladde oppervlakken.

Bovendien heeft de ELID-slijptechnologie ook de kenmerken van een eenvoudig proces en een flexibele bediening, die gemakkelijk te promoten en toe te passen is in de industriële productie. Door voortdurende optimalisatie van maalparameters en procesomstandigheden kunnen de verwerkingsefficiëntie en verwerkingskwaliteit van aluminiumnitride-keramiek verder worden verbeterd om te voldoen aan de groeiende vraag naar hoogwaardige materialen op het gebied van micro-elektronica-verpakkingen.

Samenvattend heeft het ELID-slijpproces, met zijn unieke voordelen, een groot potentieel getoond bij het oplossen van de verwerkingsproblemen veroorzaakt door de hoge hardheid, hoge brosheid en lage breuktaaiheid van aluminiumnitride-keramiek. Door deze technologie kunnen niet alleen de oppervlaktedefecten en ondergrondse schade in het verwerkingsproces effectief worden verminderd, maar ook de verwerkingsefficiëntie en verwerkingskwaliteit aanzienlijk worden verbeterd, wat een solide basis legt voor de brede toepassing van aluminiumnitride-keramiek op het gebied van elektronische verpakking. Er wordt aangenomen dat in de toekomst, met de voortdurende ontwikkeling en verbetering van de ELID-slijptechnologie, de toepassingsmogelijkheden ervan op het gebied van ultraprecieze bewerking breder zullen zijn en zullen bijdragen aan de voortdurende vooruitgang van de micro-elektronicatechnologie.