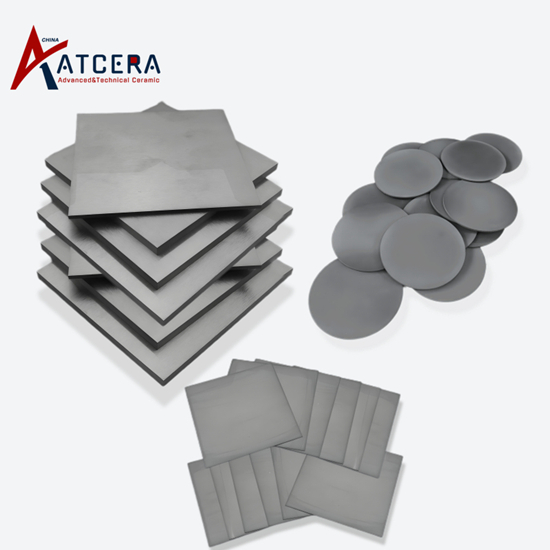

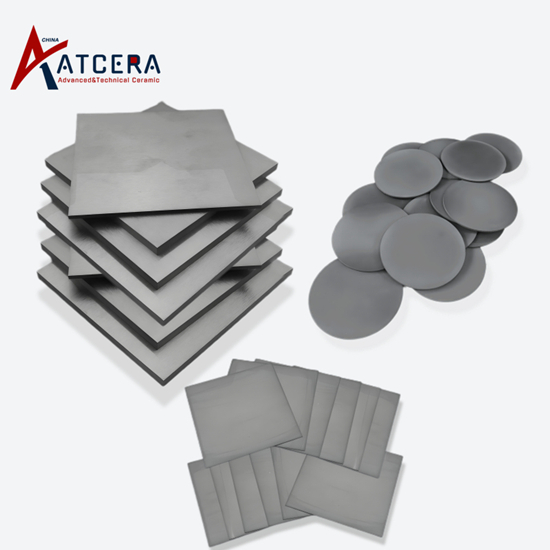

In de dynamische wereld van geavanceerde elektronica ligt de sleutel om voorop te blijven in het meedogenloze streven naar innovatie. Terwijl de technologie zich in een snel tempo blijft ontwikkelen, komen hoogwaardige Si3N4-halfgeleidersubstraten naar voren als koplopers in het revolutioneren van de industrie. Met hun uitzonderlijke thermische stabiliteit, mechanische sterkte en elektrische isolatie-eigenschappen ontketenen Si3N4-substraten de ware kracht van geavanceerde elektronica als nooit tevoren.

Door Si3N4-substraten in elektronische apparaten te integreren, kunnen fabrikanten de grenzen van prestaties en efficiëntie verleggen. Deze substraten verbeteren de vermogensverwerkingsmogelijkheden van elektronische componenten, waardoor snellere gegevensoverdrachtsnelheden, verbeterd thermisch beheer en verhoogde betrouwbaarheid mogelijk zijn. Of het nu gaat om smartphones, auto-elektronica of ruimtevaarttoepassingen, Si3N4-substraten transformeren de manier waarop we technologie ervaren.

Terwijl de vraag naar snelle, betrouwbare en energiezuinige elektronica blijft groeien, staan Si3N4-halfgeleidersubstraten klaar om de industrie de toekomst in te leiden. Hun unieke combinatie van sterkte en isolerende eigenschappen maakt ze tot een essentieel ingrediënt in de ontwikkeling van geavanceerde elektronische apparaten.

Zet uw gordel dus vast en bereid u voor op het verkennen van de grenzeloze mogelijkheden die Si3N4-halfgeleidersubstraten met zich meebrengen. De toekomst van geavanceerde elektronica begint hier.

Voordelen van Si3N4 halfgeleidersubstraten

Siliciumnitride (Si3N4) halfgeleidersubstraten zijn uitgegroeid tot een gamechanger in de wereld van geavanceerde elektronica en bieden een groot aantal voordelen die een revolutie teweegbrengen in de industrie. Een van de belangrijkste voordelen van Si3N4-substraten is hun uitzonderlijke thermische stabiliteit. In tegenstelling tot traditionele halfgeleidermaterialen is Si3N4 bestand tegen hoge temperaturen zonder de structurele integriteit of elektrische eigenschappen in gevaar te brengen. Deze thermische veerkracht is cruciaal in toepassingen waarbij elektronische componenten worden blootgesteld aan intense hitte, zoals in vermogenselektronica, hoogfrequente apparaten en auto-elektronica.

Een ander belangrijk voordeel van Si3N4-substraten is hun uitzonderlijke mechanische sterkte. Deze substraten staan bekend om hun vermogen om hoge niveaus van spanning en spanning te weerstaan, waardoor ze een ideale keuze zijn voor toepassingen waarbij duurzaamheid en betrouwbaarheid van het allergrootste belang zijn. Deze mechanische sterkte vertaalt zich ook in een verbeterde warmteafvoer, omdat de substraten warmte effectief kunnen afvoeren van gevoelige elektronische componenten, waardoor de algehele systeemprestaties en levensduur worden verbeterd.

Furthermore, Si3N4 semiconductor substrates possess excellent electrical insulation properties, which is a critical factor in the design and fabrication of high-performance electronic devices. These substrates effectively isolate electrical signals, preventing cross-talk and ensuring signal integrity, which is essential for applications such as radio frequency (RF) and high-speed digital circuits. This insulating property also contributes to the improved power handling capabilities of Si3N4-based electronic devices, enabling them to operate at higher voltages and power levels without compromising reliability.

Applications of Si3N4 semiconductor substrates in advanced electronics

The exceptional properties of Si3N4 semiconductor substrates have made them an indispensable component in a wide range of advanced electronic applications. In the realm of power electronics, Si3N4 substrates are widely used in the manufacture of high-power transistors, inverters, and motor drives. These substrates provide the necessary thermal management and electrical insulation, allowing power electronic devices to operate at higher voltages and switching frequencies, resulting in improved efficiency and reliability.

In the automotive industry, Si3N4 semiconductor substrates have become increasingly prevalent, particularly in the design of electronic control units (ECUs) and other safety-critical components. The robust mechanical properties and thermal stability of these substrates ensure that automotive electronics can withstand the harsh environmental conditions encountered in vehicles, such as extreme temperatures, vibrations, and shocks. This, in turn, enhances the overall reliability and safety of modern automobiles.

The aerospace and defense sectors have also embraced the use of Si3N4 semiconductor substrates, as these applications often demand the highest levels of performance and reliability. In these industries, Si3N4 substrates are utilized in a variety of electronic systems, including radar, avionics, and satellite communications. The unique combination of thermal, mechanical, and electrical properties offered by Si3N4 substrates enables the development of advanced electronic systems that can operate reliably in the demanding environments encountered in aerospace and defense applications.

The future of Si3N4 semiconductor substrates in the electronics industry

As the demand for faster, more efficient, and more reliable electronic devices continues to grow, the role of Si3N4 semiconductor substrates in shaping the future of the electronics industry cannot be overstated. With the ever-increasing complexity and power requirements of modern electronic systems, the exceptional properties of Si3N4 substrates make them an increasingly attractive choice for manufacturers and designers.

Looking ahead, the integration of Si3N4 semiconductor substrates into a wide range of electronic devices is expected to accelerate. From next-generation smartphones and wearables to cutting-edge industrial automation and renewable energy systems, Si3N4 substrates will play a crucial role in enabling the development of high-performance, energy-efficient, and reliable electronic components.

Furthermore, the ongoing research and development in the field of Si3N4 substrate manufacturing processes are expected to drive further advancements in the technology. Improvements in material quality, manufacturing techniques, and cost-effectiveness will likely lead to the widespread adoption of Si3N4 substrates across the electronics industry, solidifying their position as the preferred choice for a wide range of applications.

Manufacturing process of Si3N4 semiconductor substrates

The manufacturing of high-quality Si3N4 semiconductor substrates involves a complex and meticulous process that requires precise control over various parameters. The production of Si3N4 substrates typically begins with the synthesis of the raw material, silicon nitride, through a chemical reaction between silicon and nitrogen.

One of the most common methods for producing Si3N4 is the chemical vapor deposition (CVD) process, where silicon and nitrogen-containing precursor gases are introduced into a reaction chamber and subjected to high temperatures. This process allows for the controlled deposition of a thin, uniform layer of Si3N4 on a suitable substrate, such as silicon or sapphire.

Following the Si3N4 deposition, the substrate undergoes a series of precision machining and polishing steps to ensure a smooth, defect-free surface. This surface preparation is crucial, as it directly impacts the performance and reliability of the electronic devices that will be fabricated on the substrate.

To further enhance the properties of the Si3N4 substrate, various post-processing techniques may be employed, such as thermal annealing or the application of protective coatings. These additional steps help to optimize the substrate's thermal, mechanical, and electrical characteristics, making it better suited for specific electronic applications.

The manufacturing of Si3N4 semiconductor substrates requires a high level of expertise, advanced equipment, and stringent quality control measures to ensure the production of consistently reliable and high-performing materials. As the demand for these substrates continues to grow, manufacturers are continuously innovating and improving their processes to meet the ever-evolving needs of the electronics industry.

Key properties and characteristics of Si3N4 semiconductor substrates

The exceptional properties and characteristics of Si3N4 semiconductor substrates are what make them so valuable in the world of advanced electronics. One of the most notable features of Si3N4 is its exceptional thermal stability, which allows it to withstand high temperatures without compromising its structural integrity or electrical performance. This thermal resilience is particularly crucial in power electronics and high-power applications, where the substrate must be able to effectively dissipate heat generated by the electronic components.

In addition to its thermal stability, Si3N4 is renowned for its exceptional mechanical strength and hardness. These properties contribute to the substrate's ability to withstand high levels of stress and strain, making it an ideal choice for applications where durability and reliability are paramount, such as in automotive electronics and aerospace systems.

Another key characteristic of Si3N4 semiconductor substrates is their excellent electrical insulation properties. These substrates are highly effective at isolating electrical signals, preventing cross-talk and ensuring signal integrity, which is essential for high-frequency and high-speed digital circuits. This insulating capability also allows Si3N4-based electronic devices to operate at higher voltages and power levels without compromising reliability.

Furthermore, Si3N4 substrates exhibit a low coefficient of thermal expansion, which closely matches that of the semiconductor materials commonly used in electronic devices. This thermal compatibility helps to minimize the risk of thermal-induced stresses and failures, contributing to the overall reliability and performance of the electronic systems.

The combination of these exceptional properties – thermal stability, mechanical strength, electrical insulation, and thermal compatibility – makes Si3N4 semiconductor substrates a highly sought-after material in the electronics industry, enabling the development of cutting-edge electronic devices that are more powerful, efficient, and reliable than ever before.

Challenges and limitations of Si3N4 semiconductor substrates

While Si3N4 semiconductor substrates offer numerous advantages, they are not without their challenges and limitations. One of the primary challenges in the widespread adoption of Si3N4 substrates is the relatively higher cost compared to traditional semiconductor materials, such as silicon or gallium arsenide.

The manufacturing process of Si3N4 substrates is complex and requires specialized equipment, as well as a high level of expertise and quality control measures. This, in turn, can drive up the overall production costs, making Si3N4 substrates less accessible for some manufacturers, especially in price-sensitive markets.

Another limitation of Si3N4 substrates is their relatively lower thermal conductivity compared to some other semiconductor materials, such as silicon carbide (SiC) or diamond. While Si3N4 substrates exhibit excellent thermal stability, their ability to dissipate heat may be slightly less efficient in certain high-power applications, where the thermal management requirements are particularly demanding.

Additionally, the manufacturing of large-diameter Si3N4 substrates can be more challenging and may result in higher defect rates, limiting the availability of large-scale wafers for high-volume production. This can be a constraint for manufacturers who require larger substrate sizes to meet their specific design and production needs.

Despite these challenges, the electronics industry is continuously working to address the limitations of Si3N4 substrates through ongoing research and development.

Advancements in manufacturing processes, material engineering, and cost-reduction strategies are expected to help overcome these obstacles and further drive the adoption of Si3N4 substrates in the future.

Comparison of Si3N4 semiconductor substrates with other semiconductor materials

When it comes to semiconductor substrates, Si3N4 stands out as a unique and highly capable material, offering a combination of properties that are often unmatched by other semiconductor materials. One of the primary advantages of Si3N4 over traditional silicon (Si) substrates is its superior thermal stability and mechanical strength.

While silicon is a widely used semiconductor material, it can be susceptible to thermal degradation and mechanical failures at high temperatures or under high-stress conditions. In contrast, Si3N4 substrates can withstand much higher temperatures and exhibit greater resistance to mechanical stress, making them a better choice for power electronics, high-frequency, and harsh-environment applications.

Another semiconductor material that has gained significant attention in recent years is silicon carbide (SiC). Like Si3N4, SiC also offers excellent thermal stability and mechanical strength, making it a viable alternative for advanced electronic applications. However, Si3N4 substrates generally have a lower coefficient of thermal expansion, which can be advantageous in terms of thermal compatibility with semiconductor devices and reduced thermal-induced stresses.

Gallium nitride (GaN) is another semiconductor material that has seen increasing adoption in high-power and high-frequency electronics. While GaN-based devices can offer excellent performance, they often require specialized substrate materials, such as sapphire or SiC, to support their unique properties. In this context, Si3N4 substrates can serve as a cost-effective and compatible alternative, providing a suitable platform for the integration of GaN-based components.

In terms of electrical insulation properties, Si3N4 substrates outperform many other semiconductor materials, including silicon and gallium arsenide (GaAs). This superior insulation capability allows Si3N4-based electronic devices to operate at higher voltages and switching frequencies, improving overall efficiency and performance.

Overall, the unique combination of thermal, mechanical, and electrical characteristics of Si3N4 semiconductor substrates makes them a highly versatile and attractive choice for a wide range of advanced electronic applications, where the demand for high-performance, reliable, and efficient devices continues to grow.

Importance of high-performance Si3N4 semiconductor substrates in the development of advanced electronics

The role of high-performance Si3N4 semiconductor substrates in the development of advanced electronics cannot be overstated. As the electronics industry continues to push the boundaries of performance, efficiency, and reliability, these exceptional substrates have become an essential component in the quest for technological breakthroughs.

One of the key drivers behind the importance of Si3N4 substrates is the growing demand for power-dense and energy-efficient electronic devices. In industries such as automotive, aerospace, and renewable energy, the ability to handle high power levels while maintaining thermal stability and reliability is crucial. Si3N4 substrates, with their exceptional thermal management capabilities and mechanical strength, enable the design and manufacture of electronic components that can operate reliably under these demanding conditions.

Furthermore, the insulating properties of Si3N4 substrates are crucial in the development of high-frequency and high-speed electronic devices, such as those used in telecommunications, radar systems, and advanced computing. By effectively isolating electrical signals and preventing cross-talk, Si3N4 substrates help to ensure the integrity and performance of these mission-critical electronic systems.

As the world becomes increasingly reliant on advanced electronics, the need for reliable, durable, and efficient devices has never been more pressing. Si3N4 semiconductor substrates play a pivotal role in meeting these demands, enabling the creation of innovative electronic products that are better equipped to handle the challenges of the modern world.

From smartphones and wearables to industrial automation and renewable energy systems, the integration of high-performance Si3N4 substrates is transforming the electronics industry, paving the way for a future where advanced electronics are more powerful, efficient, and reliable than ever before.

Conclusion: The potential and outlook of Si3N4 semiconductor substrates in the electronics industry

Terwijl de elektronica-industrie zich in een snel tempo blijft ontwikkelen, is de rol van Si3N4-halfgeleidersubstraten bij het vormgeven van de toekomst van geavanceerde elektronica steeds duidelijker geworden. Deze uitzonderlijke materialen, met hun ongeëvenaarde thermische stabiliteit, mechanische sterkte en elektrische isolatie-eigenschappen, staan klaar om een cruciale rol te spelen in de ontwikkeling van geavanceerde elektronische apparaten die krachtiger, efficiënter en betrouwbaarder zijn dan ooit tevoren.

Het potentieel van Si3N4-substraten is enorm, omdat ze naadloos kunnen worden geïntegreerd in een breed scala aan elektronische toepassingen, van vermogenselektronica en hoogfrequente apparaten tot auto- en ruimtevaartsystemen. Terwijl de vraag naar snelle, betrouwbare en energiezuinige elektronica blijft groeien, zullen Si3N4-substraten voorop blijven lopen op het gebied van technologische innovatie, waardoor fabrikanten de grenzen van wat mogelijk is kunnen verleggen.

Vooruitkijkend is de toekomst van Si3N4-halfgeleidersubstraten in de elektronica-industrie veelbelovend. Aanhoudende onderzoeks- en ontwikkelingsinspanningen zullen naar verwachting verdere verbeteringen in de materiaalkwaliteit, productieprocessen en kosteneffectiviteit stimuleren, wat uiteindelijk zal leiden tot de wijdverbreide acceptatie van deze substraten in de industrie.

Naarmate het elektronicalandschap zich blijft ontwikkelen, zullen de veelzijdigheid en prestaties van Si3N4-substraten ze tot een steeds onmisbaarder onderdeel maken in de zoektocht naar geavanceerde, hoogwaardige elektronische apparaten. Van de slanke smartphones in onze broekzakken tot de geavanceerde elektronische systemen in onze vliegtuigen: de impact van Si3N4-substraten zal voelbaar zijn in een breed scala van industrieën, waardoor de toekomst van de technologie zoals wij die kennen vorm wordt gegeven.

Concluderend kan worden gesteld dat het potentieel van Si3N4-halfgeleidersubstraten in de elektronica-industrie werkelijk grenzeloos is. Naarmate de vraag naar snellere, efficiëntere en betrouwbaardere elektronische apparaten blijft groeien, zullen deze uitzonderlijke materialen ongetwijfeld een cruciale rol spelen bij het inluiden van een nieuw tijdperk van geavanceerde elektronica, waardoor de manier waarop we omgaan met en ervaren van de wereld om ons heen verandert.